-

JAN 2026PICO FIDO KEY RP2040 CASE

A simple 3D-printed USB-A case and adapter for RP2040 USB-C boards. This enclosure lets you turn an RP2040 into a USB-A FIDO security key, making it easy to tinker with FIDO2 authentication and USB HID in a compact, pocket-friendly form. Read more about pico-fido project | Get 3D model for print |

-

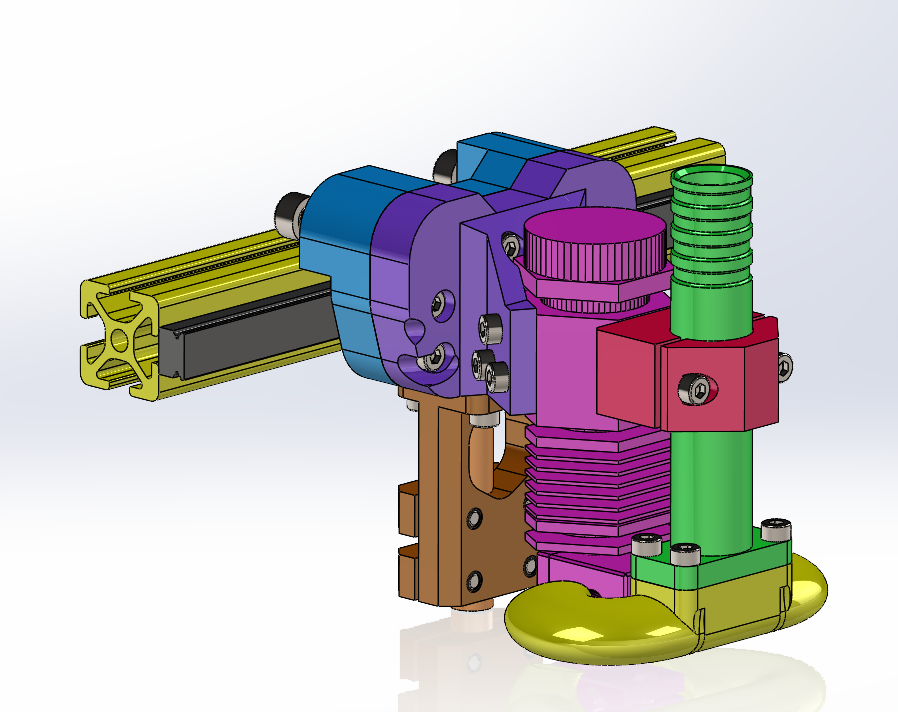

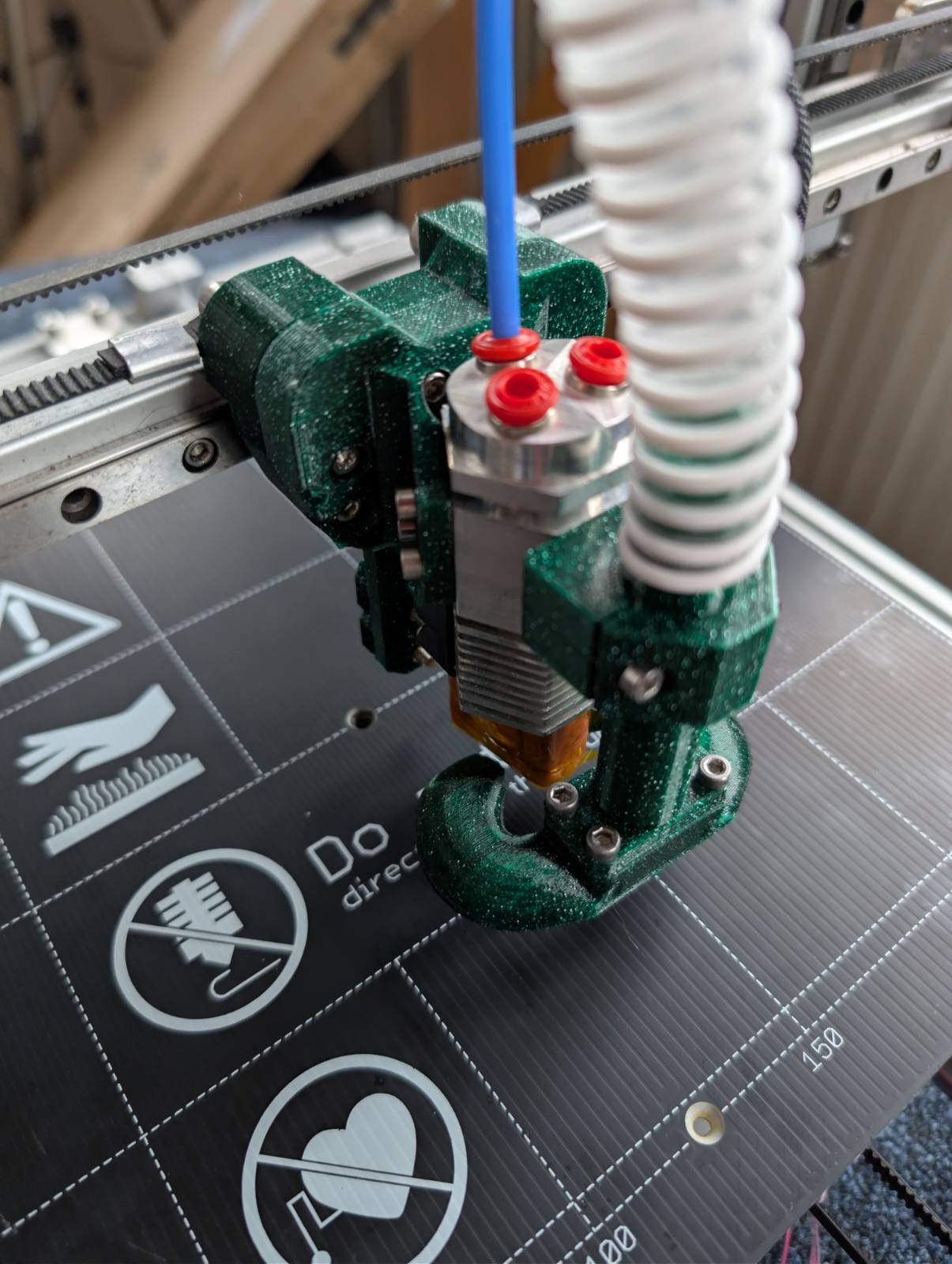

DEC 20253-Color Extruder THC-01 • Prinda Sensor • Fanduct V2

-

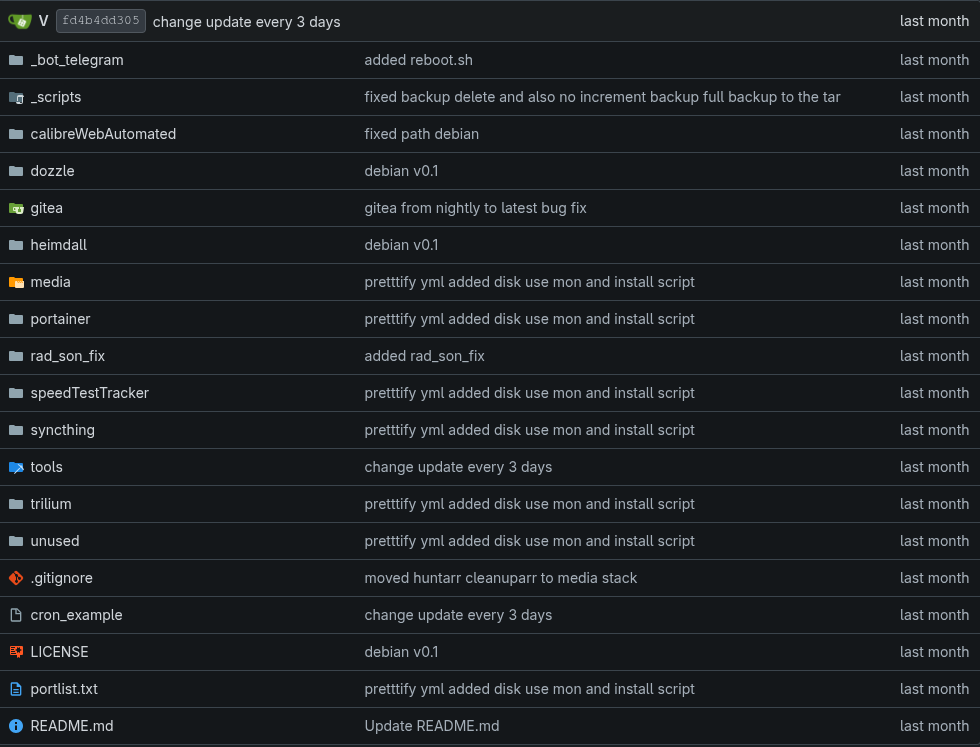

DEC 2025Docker Lazy

DOCKER | LINUX | SHELL

Docker Lazy is a library of organized, reliable Docker Compose files designed to help developers, DevOps engineers, and self-hosters spin up containers effortlessly. Instead of searching for examples or debugging broken configs, Docker Lazy provides a wide set of pre-tested, structured, plug-and-play Compose templates for common services and complete application stacks.

-

NOV 20253-Color Extruder THC-01 • Prinda Sensor • Fanduct V1

-

SEP 2025Borderlands-Inspired Cyberpunk Claptrap

Blender 3D Modeling: Hard Ops, Machin3 Tools, Boxcutter.

I explored advanced Blender modeling workflows using add-ons such as Hard Ops, Machin3 Tools, MechMachine, and Boxcutter. These tools allowed me to efficiently create complex hard-surface models, sharpen mechanical details, and improve overall modeling speed and precision.

-

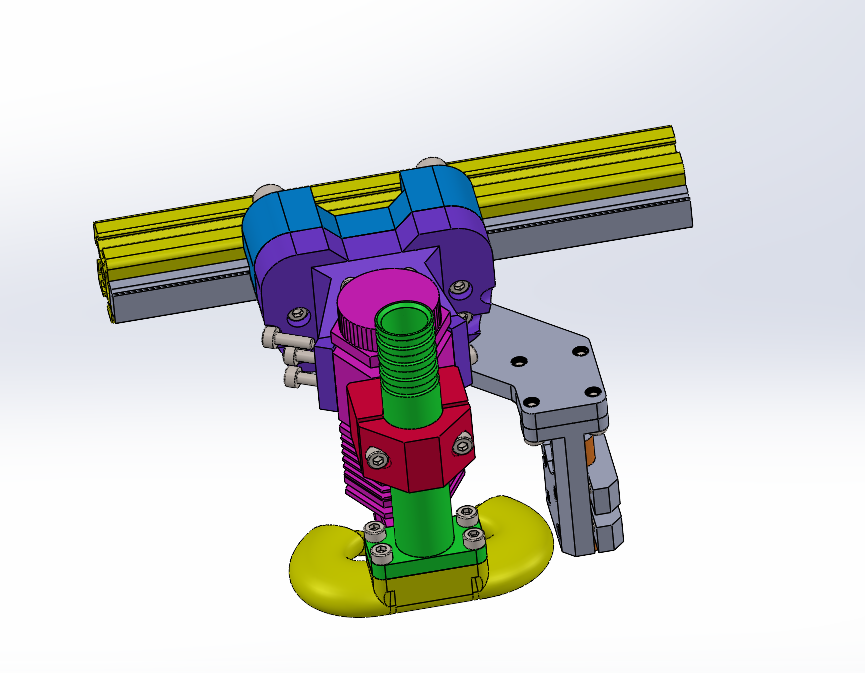

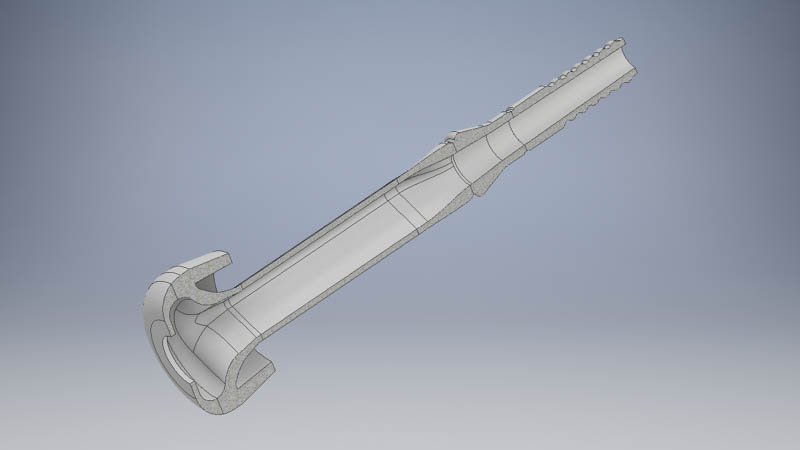

MAY - DEC 2024-2025Plasma Pipe Cutter

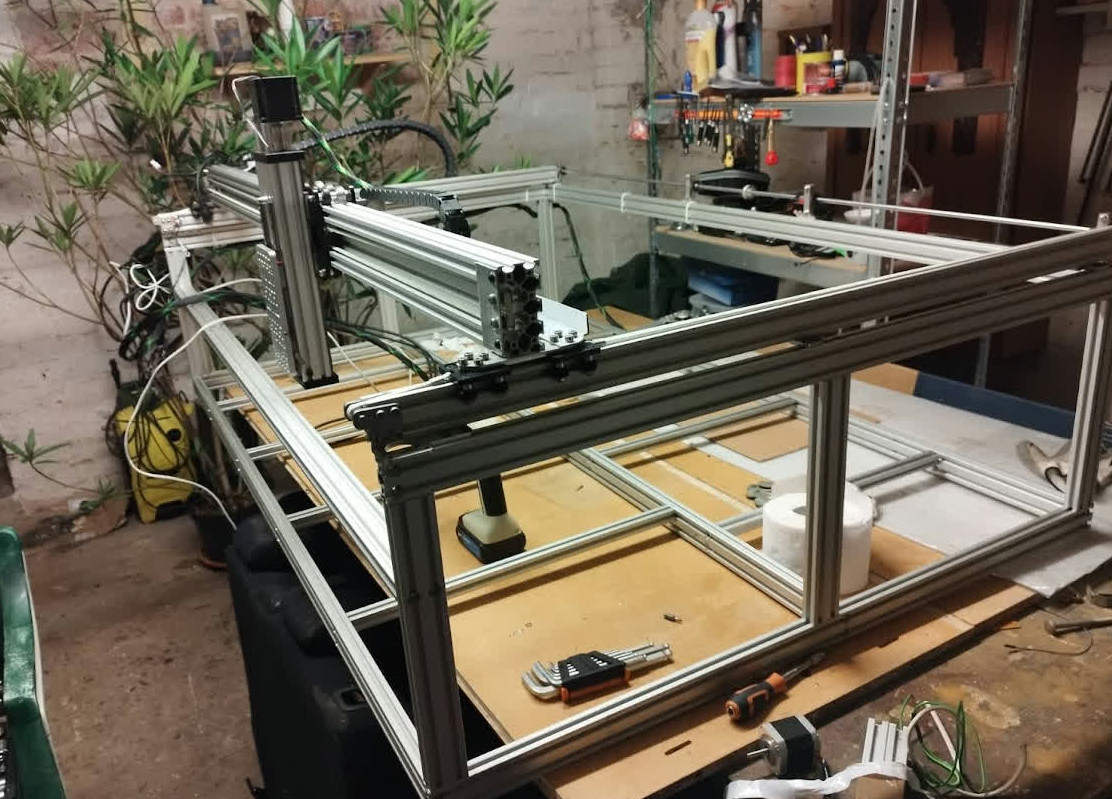

I designed and began building a 4-axis plasma cutting machine for profiling metal components. The project involved mechanical design, motion system integration, and control electronics for precise multi-axis cutting. Due to a flood, the project had to be paused and currently remains in the prototype phase. Despite this, it strengthened my skills in CNC mechanics, electronics, and automation.

-

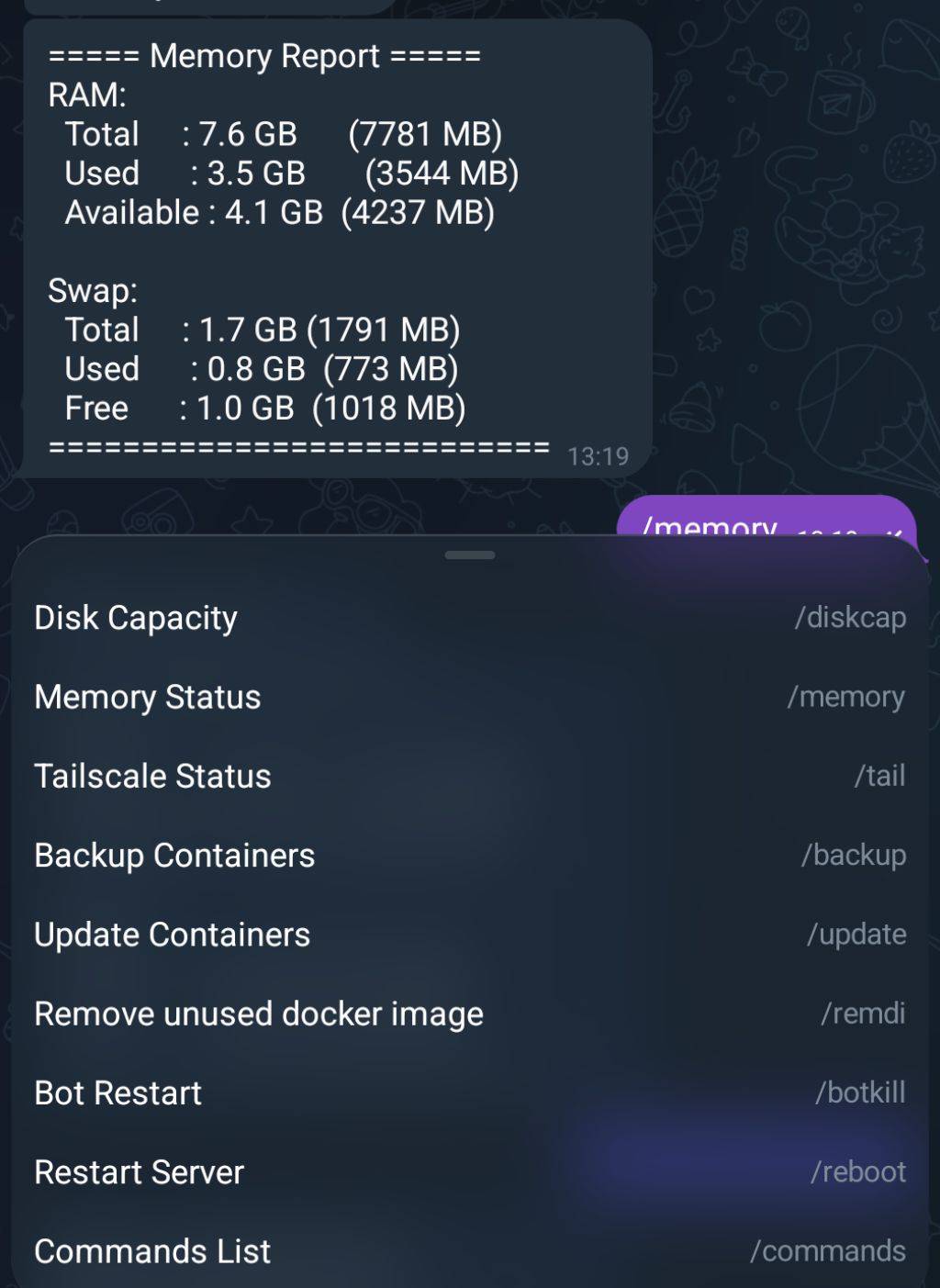

AUG 2024Server Telegram Bot

A bare-metal Telegram bot written in shell and curl, built for remote server ops, exposing system state and Docker lifecycle control through minimal, command-driven automation.

-

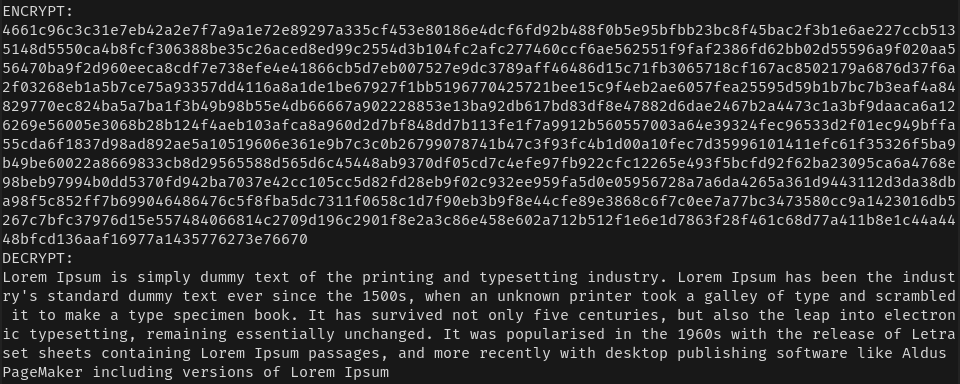

MAY 2023OpenSSL AES-256-CBC

C | LINUX | GIT | VIM

Implemented strong data encryption using OpenSSL with the AES-256-CBC algorithm to ensure confidentiality of sensitive information, including secure key and IV handling, encryption/decryption processes, and adherence to industry-standard cryptographic practices.

-

JUN 2022Kindle JAILBREAK

Jailbreak on a Kindle device to unlock advanced functionality and installed KOReader, enabling enhanced e-book reading features beyond the default Kindle software.

-

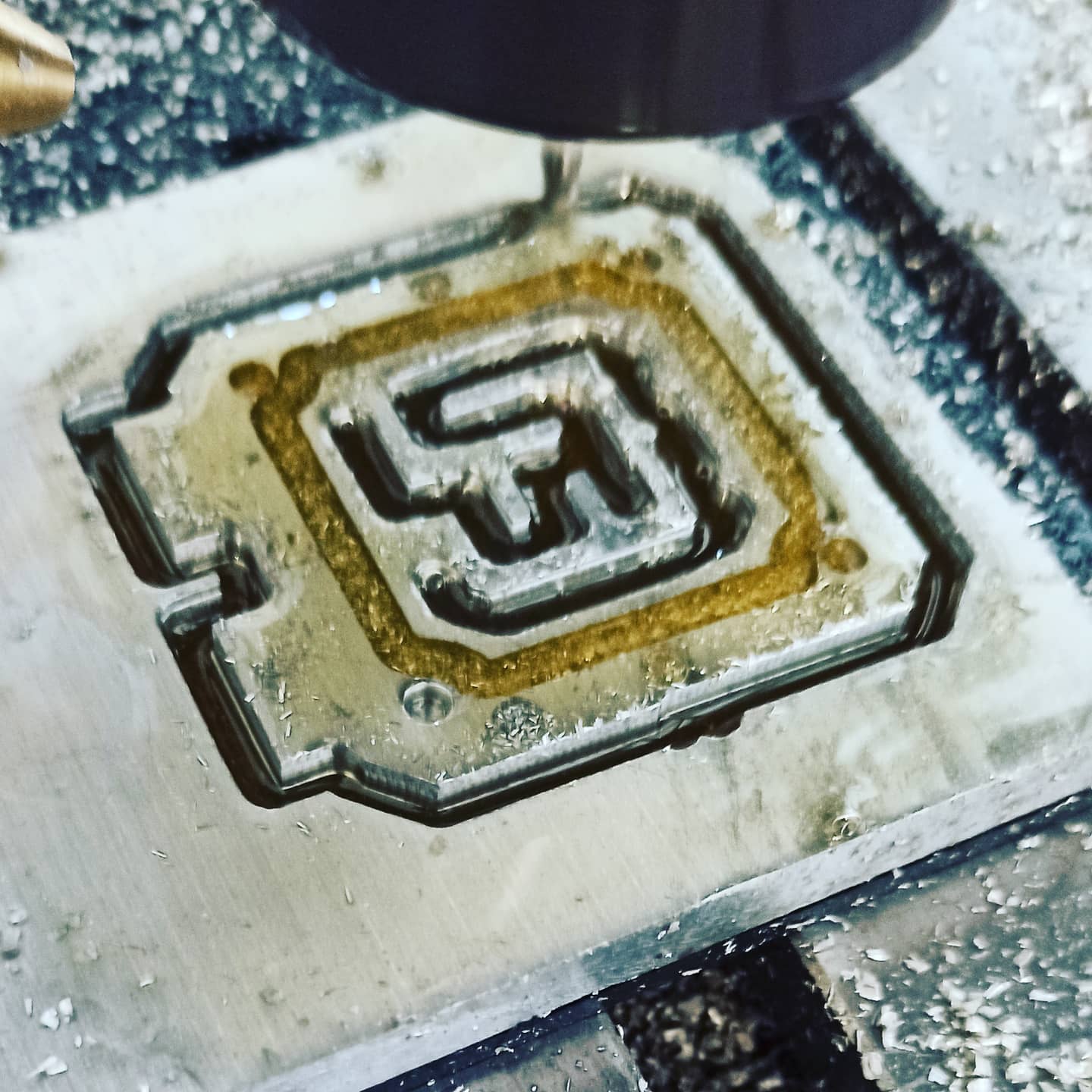

SEP 2021Nema 17 water cooling

FREECAD | MILLING CNC

-

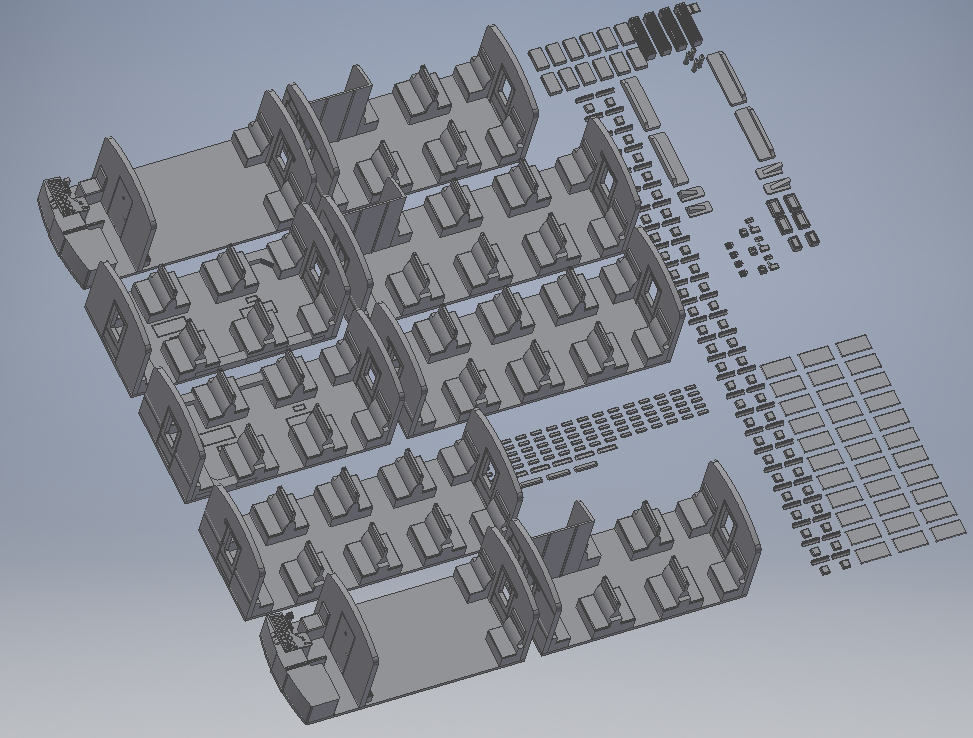

AUG 2021Flat Gantry

Autodesk Inventor | 3d printing DLP | [2016-2017]

After moving to Kraków, I was finally able to reassemble my CO₂ laser gantry. The system required a few small fixes and adjustments after the move, but everything came together without major issues. Once the gantry was fully assembled again, the project could officially restart.

Looking ahead, I plan to switch from a CO₂ laser to plasma cutting. Because of this, I redesigned the gantry to be compatible with plasma operation. The new design focuses on increased rigidity and durability, which are essential for plasma cutting. This approach allows the system to be upgraded in the future without rebuilding the entire machine.

With the gantry reassembled and redesigned, the project is now ready for the next development stage.

-

OCT 20213d Scanning

-

MAY 2019LED REG Shift

Developed embedded firmware for an STM32 microcontroller to control 80 LEDs using 10 daisy-chained shift registers. The system used direct GPIO control with a LATCH pin to manage the registers, enabling precise control of individual LEDs. The solution was optimized for reliability, scalability, and efficient low-level timing without dedicated communication peripherals.

-

JUN 2019Laser 40W co2

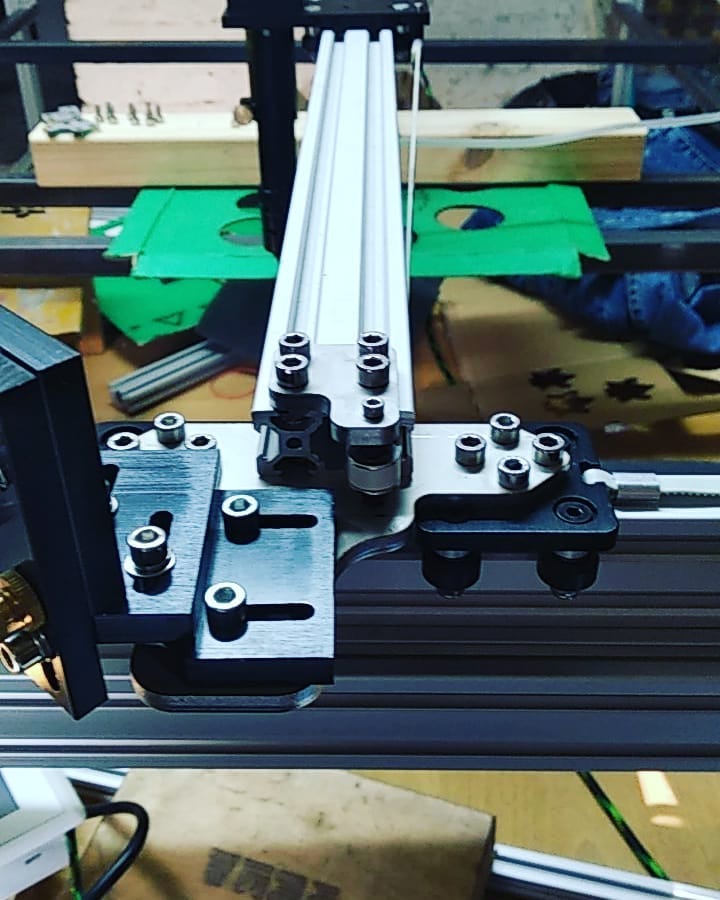

I designed and built a flat XY gantry system for a 40W CO₂ laser with a cutting area of 1.5 m × 1 m. The project involved mechanical design, precision linear motion integration, and alignment for accurate laser cutting and engraving over a large workspace. Aligning the mirrors for optimal beam path proved challenging, requiring careful calibration to ensure consistent power and focus. This project enhanced my skills in mechanical engineering, CNC motion systems, and laser setup.

-

DEC 2018SMED system

I designed a SMED (Single-Minute Exchange of Dies) system based on magnets and guide slots, allowing rapid swapping between a 3D printer head and a 2W laser module. The design minimized downtime while ensuring precise alignment and secure attachment.

-

MAY - DEC 2017 - 2019Delta 3D printer

RAMPS | RepRap | Autodesk Inventor | Soldering | Hiwin

-

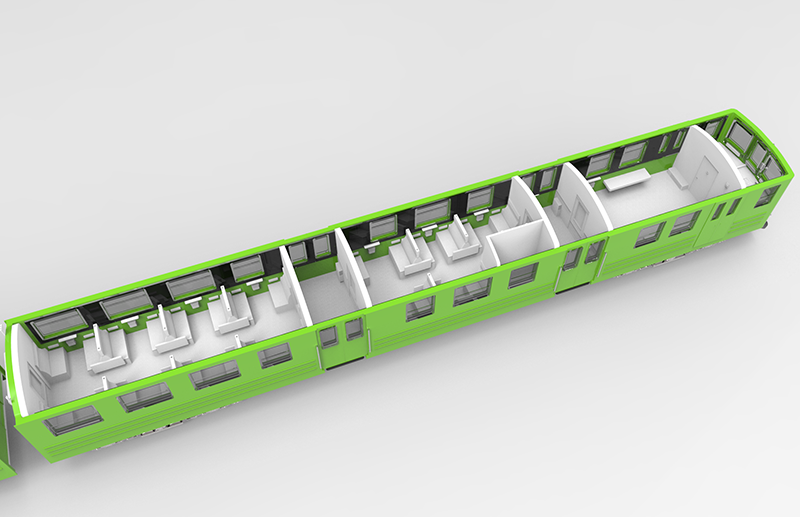

FEB - JUN 2017Train EN-57 1:87

Modeled an EN57 train in Autodesk Inventor at 1:87 scale, emphasizing accurate proportions and mechanical details.

-

JUN 2017Device for washing milking collector

-

AUG 2017Rapid Prototyping part of device for milking sheep

Autodesk Inventor | 3d printing FDM

-

SEP 2017Laser Diode 2W

Mounted a 2W laser diode on a 3D-printed Core XY prototype platform, controlled via TTL signals through a RAMPS board. Modified the Core XY mechanics for experimental testing and rapid prototyping. The project involved hardware integration, low-level signal control, and custom mechanical adaptation for laser operation on a precision motion system.

-

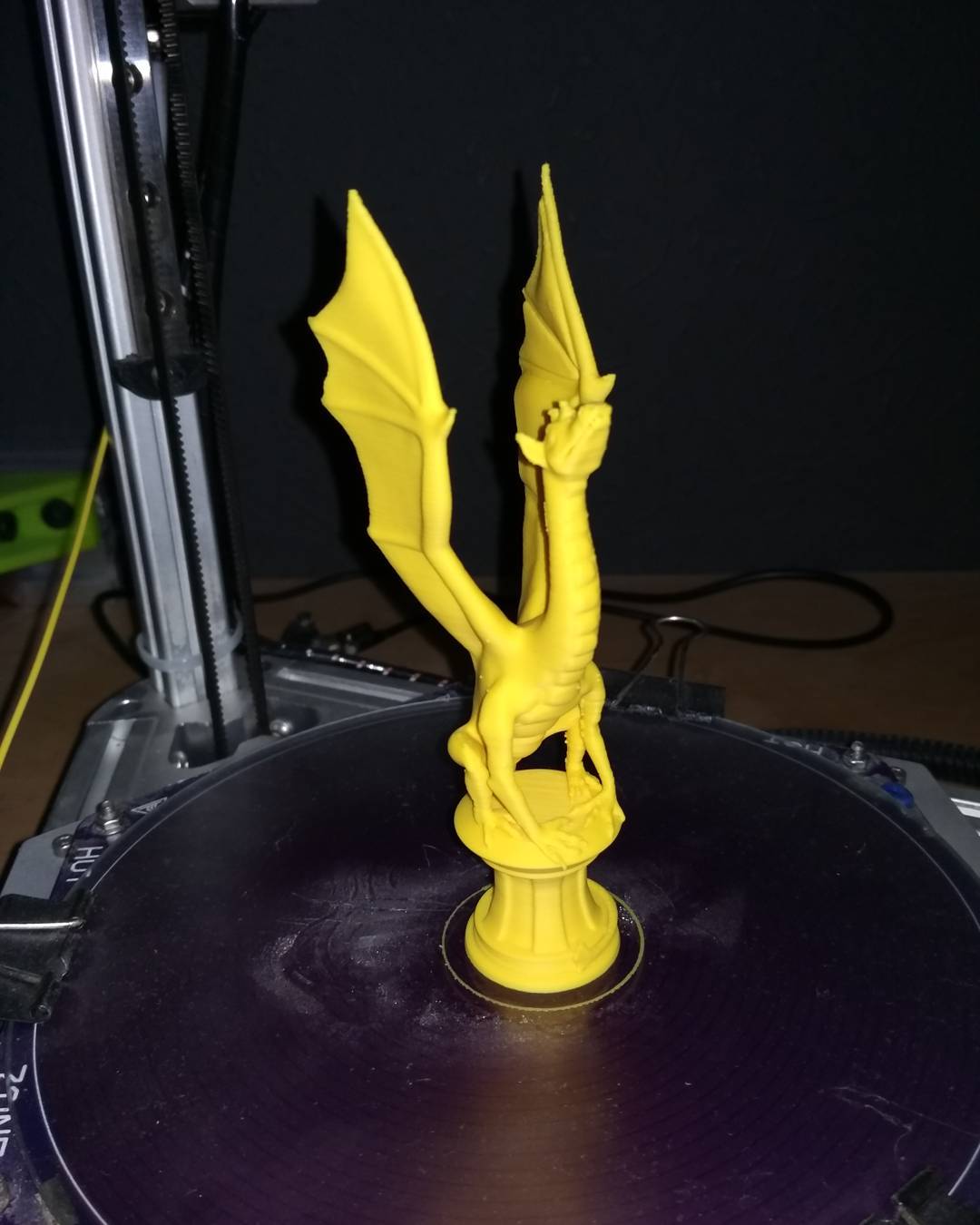

JUL 20173D printer own design

It’s a slightly funny and spontaneous story. I designed the printer in two weeks, then 3D printed all the parts, packed them into a backpack, and flew to Spain. The first assembly took place there, without any prior test build or certainty that everything would work. I didn’t even consider the possibility that it might fail. In the end, everything worked perfectly on the first assembly, validating both the design and manufacturing process.

-

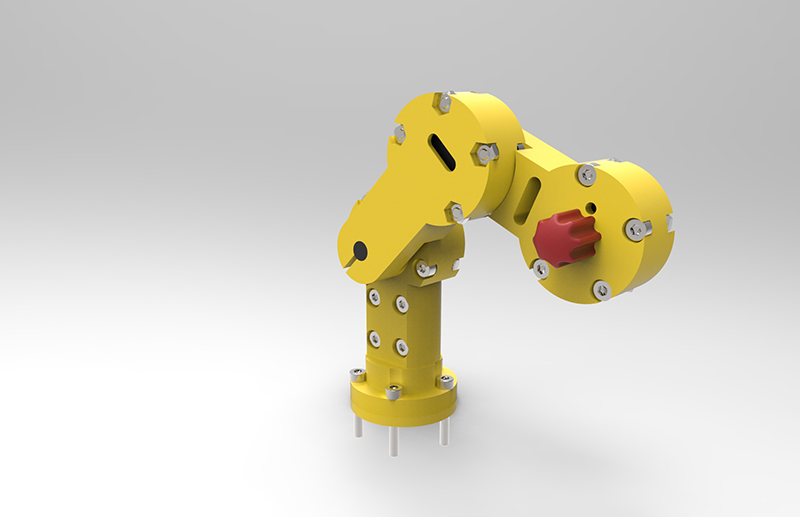

MAY 2017Robot-arm manipulator [EMBEDDED]

Designed and built an embedded robot-arm manipulator controlled by Arduino.

Created mechanical components in Autodesk Inventor, fabricated parts using 3D printing, and assembled electronics through soldering. Implemented motion control logic to achieve precise and repeatable arm movements.

-

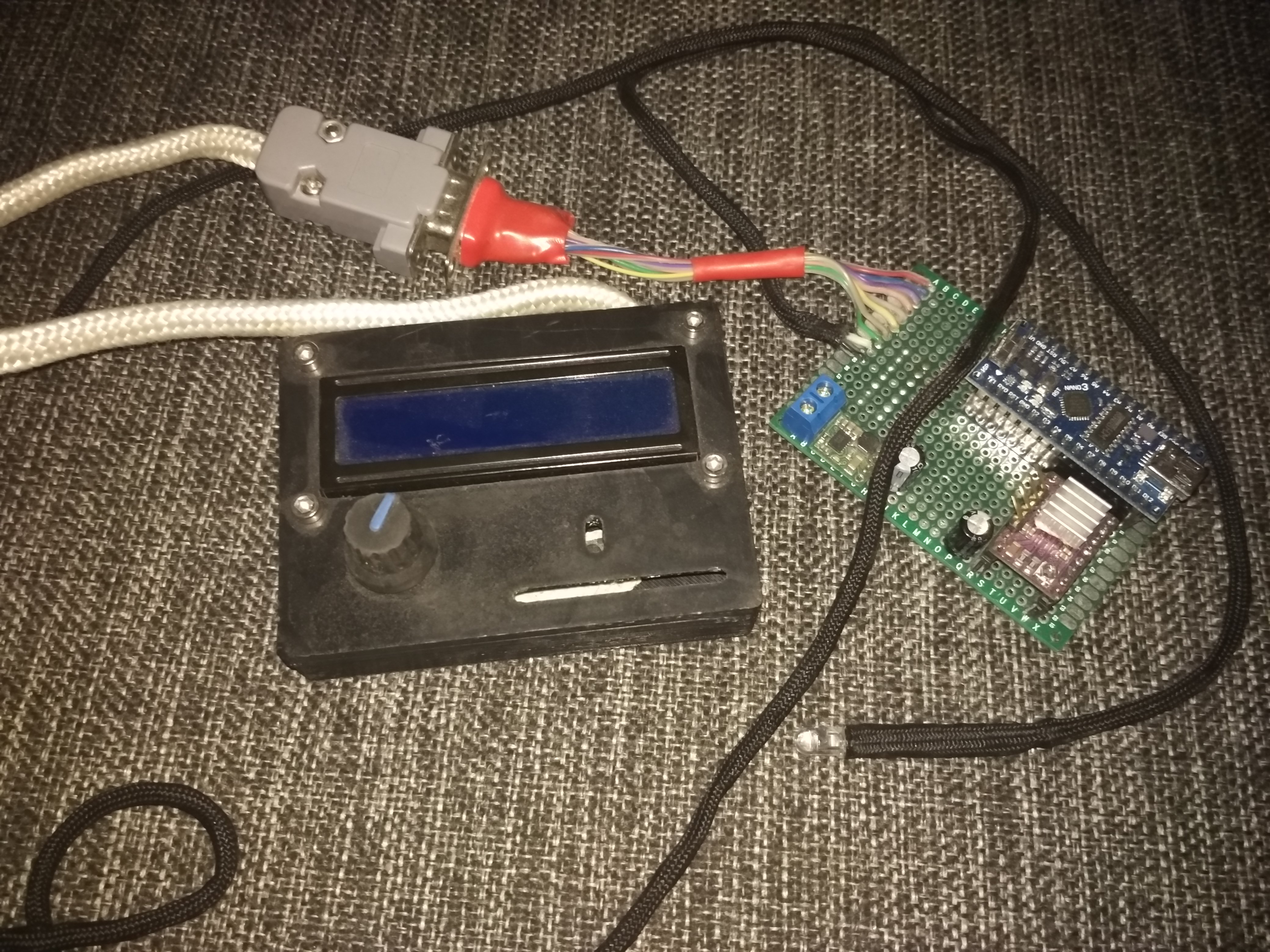

APR 2017Turn table 360 photo [EMBEDDED]

Automated 360° Product and Photography 3D scan system.

Designed and developed an automated 360° product photography setup integrating a motorized turntable and IR-based automatic camera shutter. Used Arduino (C) for motor control, sensor processing, and shutter triggering. Designed mechanical components in Autodesk Inventor and fabricated parts using 3D printing, enabling hands-free, consistent 360° image capture through rapid prototyping.

-

NOV 2016I2C Relay board for OrangePi/RPI

LINUX | GIT | I2C

-

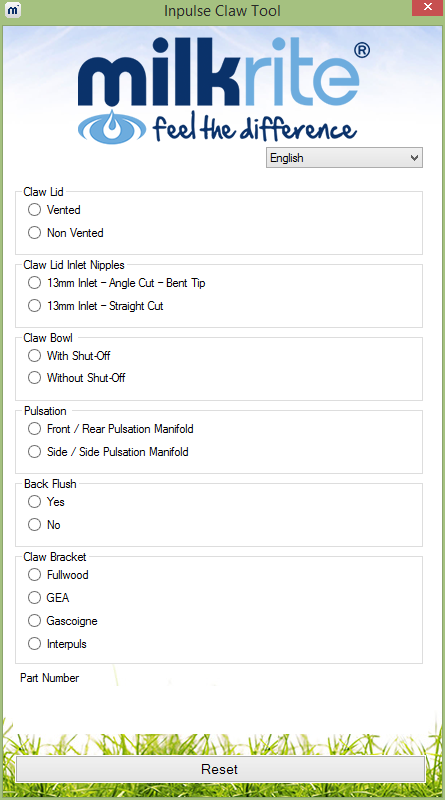

MAY - MAR 2015 - 2016Milkrite Impulse Air Claw Tool

Milkrite Impulse Air Cluster Tool

Milkrite Liner Selection Tool

C# | SQL

In 2015, I started worked for Milkrite on a multilingual (9 languages), offline component selection tool for installers and service technicians. The application ran locally on tablets and computers for farm environments with limited or no connectivity, handling complex component dependencies to significantly speed up installation, servicing, and deployment.

-

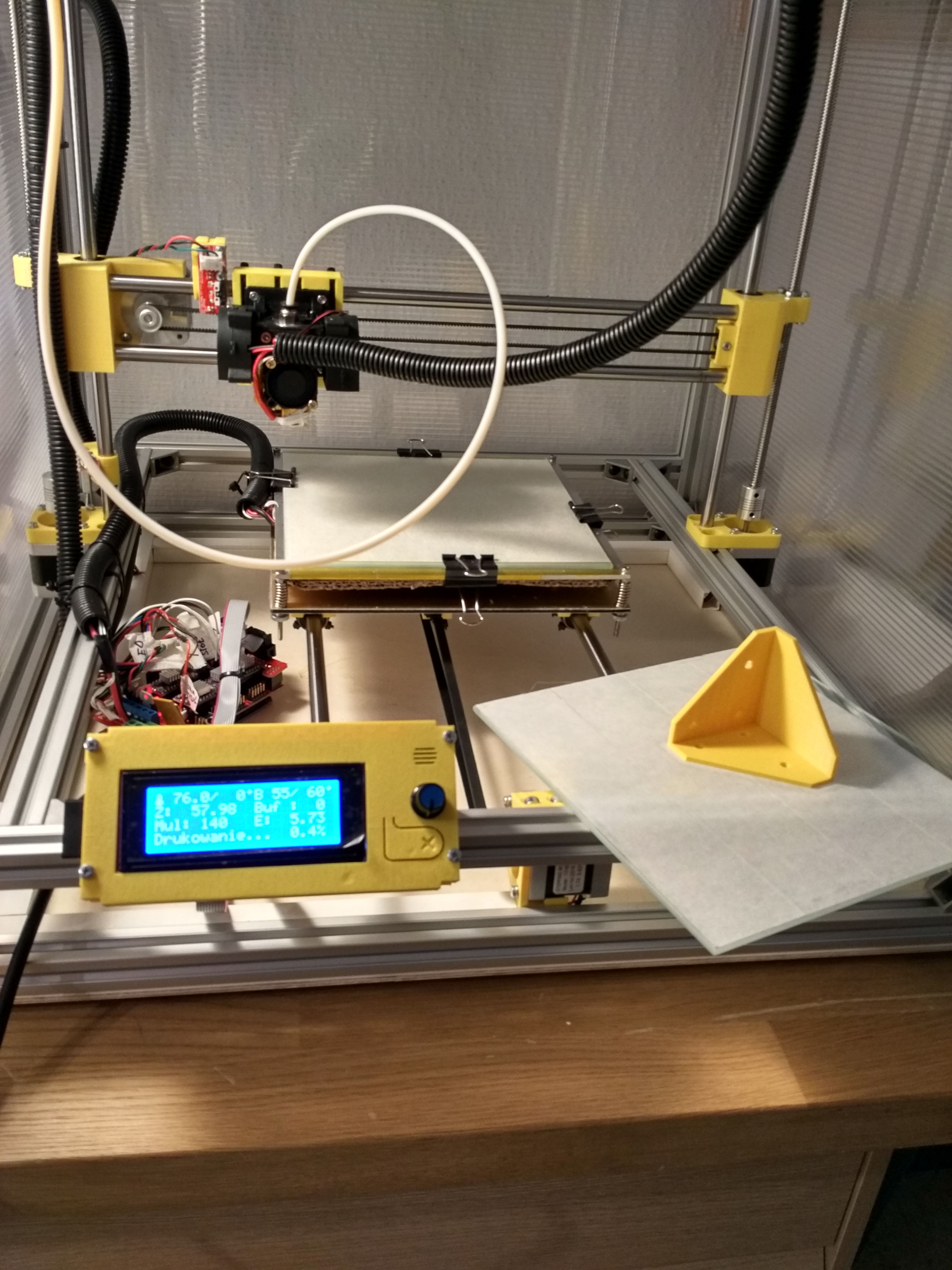

DEC 20143D printer prusa i3

In 2014, I built a Prusa i3 3D printer from parts sourced from AliExpress. The frame was constructed from wood and threaded rods, combining DIY creativity with mechanical stability. I integrated a RAMPS board and configured the printer using Repetier firmware. The project involved mechanical assembly, wiring, firmware installation, and precise calibration for layer height, bed leveling, and extrusion. I also implemented custom modifications to improve stability and print quality. This hands-on project provided strong experience in FDM 3D printing, electronics, and troubleshooting complex systems.

-

APR 2014Pararell procesing file

Linux | C | VIM | MAKE | GIT

I recreated the wc (word count) program using multithreading. The input file was divided into chunks, which were processed simultaneously by multiple threads to improve performance.orem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore

-

JUL 2014OpenCV quick color selection

PYTHON | OpenCV

I implemented color selection using OpenCV and the laptop’s built-in camera. The camera captured the screen content, which was then processed in real time to extract dominant colors and drive the LED backlight accordingly.:

-

MAY 2014Dynamic screen backlight [Embedded]

C | Arduino

This was my beginning with embedded systems.

In 2014, a friend brought me an Arduino Uno to play with. At the time, I was working on my engineering thesis in computer science. And suddenly — wait, I can actually control real-world objects. It’s how a dynamic screen backlighting system was born, based on WS2812B LEDs and serial communication. The system reacted to the content displayed on the screen, extending the image with ambient light around the monitor. This was before Ambilight became widely popular.